Process Data Sheet

EOS NickelAlloy IN939 for EOS M 400-4 I 40 µm

EOS M 400-4 - 40 µm - TRL 5

Process Information Metal

This process parameter includes two variations of the exposure set: the first one provides better productivity and overhang buildability, while the second one is designed for optimized internal feature and cooling channel accuracy.

| System Setup | EOS M 400-4 |

|---|---|

| EOS Material set | IN939_040_CoreM404 |

| Software Requirements |

EOSPRINT 2.8 or newer EOSYSTEM 2.12 or newer |

| Recoater Blade | HSS (High Speed Steel) |

| Inert gas | Argon |

| Sieve | 63 µm |

| Additional Information | |

|---|---|

| Layer Thickness | 40 µm |

| Volume Rate | up to 4 x 3.6 mm³/s |

| Wall Thickness | Typical 0.3 - 0.4 mm mm |

Chemical and Physical Properties of Parts

Chemical composition of built parts is compliant to EOS NickelAlloy IN939 powder chemical composition.

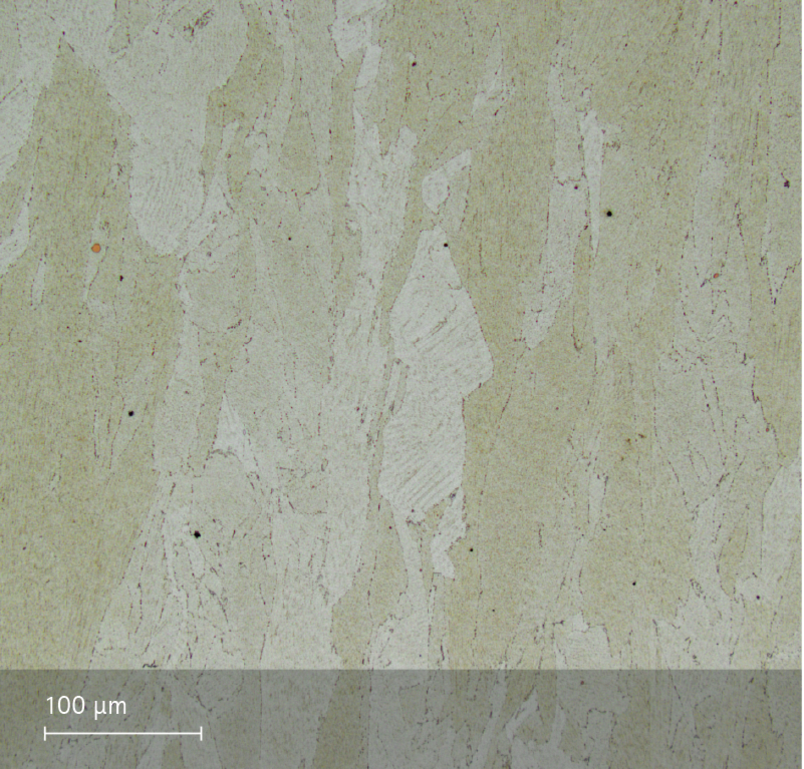

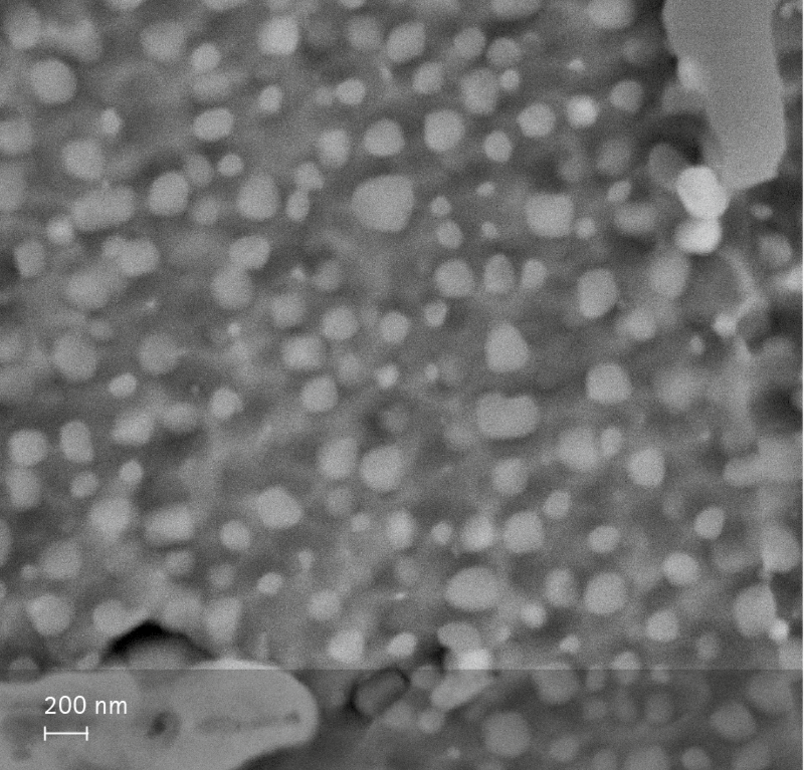

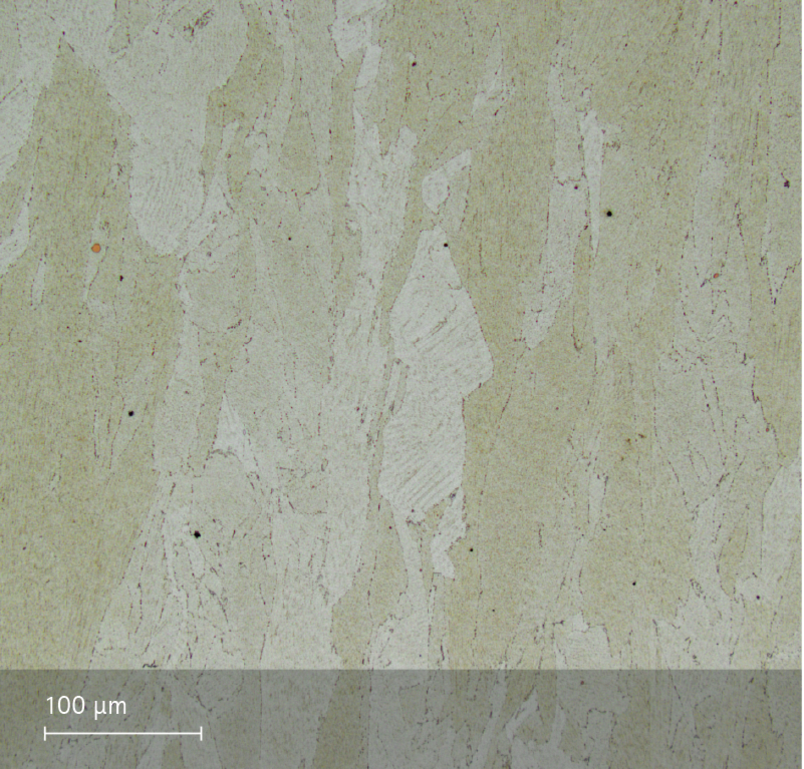

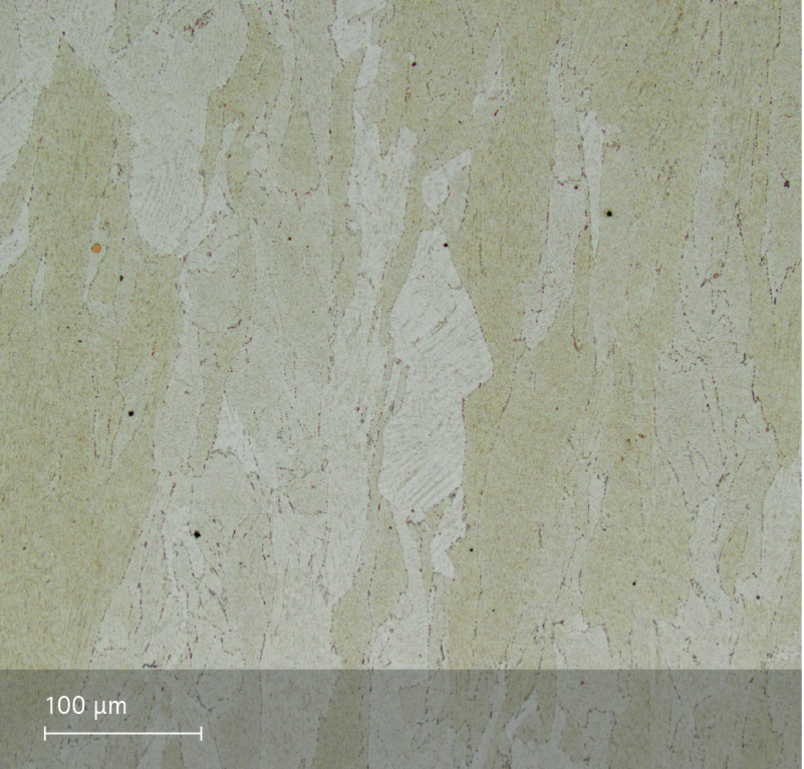

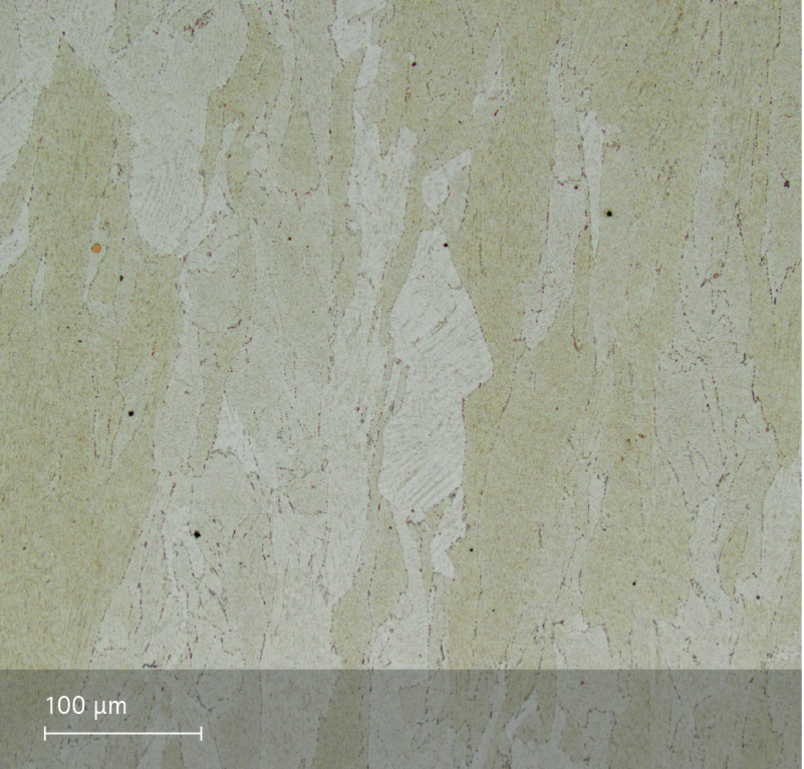

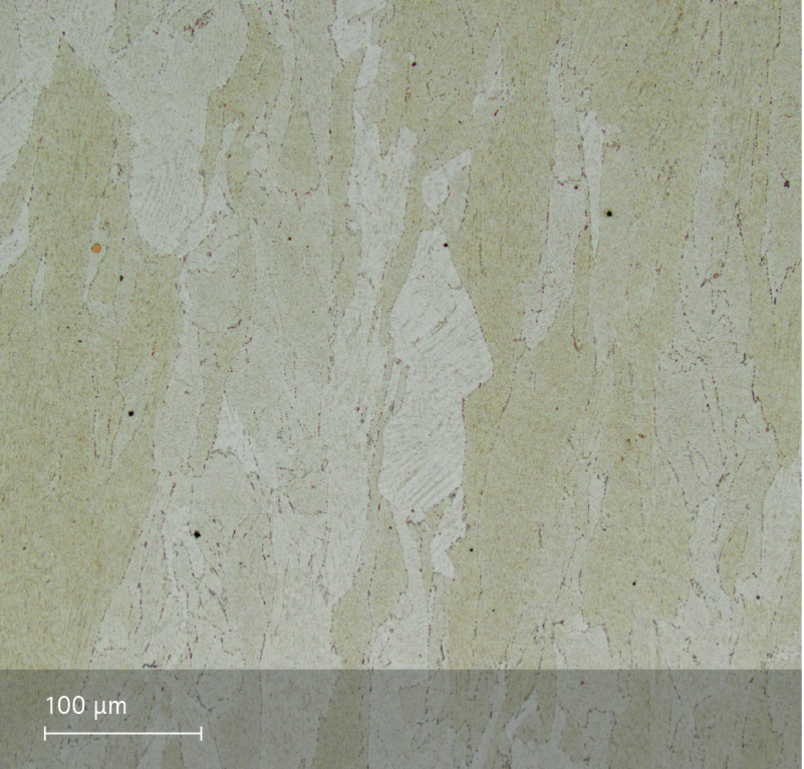

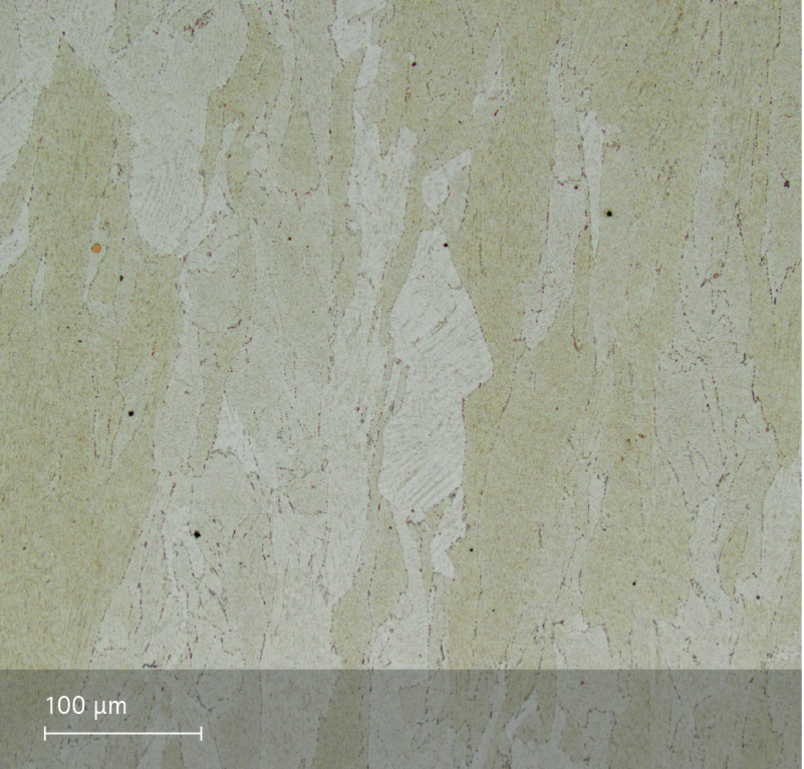

Microstructure of the Produced Parts

| Defects | Thickness | Result | Number of Samples |

|---|---|---|---|

| Average Defect Percentage | - | 0.01 % | - |

| Density EN ISO 3369 | Thickness | Result | Number of Samples |

|---|---|---|---|

| Average Density | - | > 8.15 g/cm³ | - |

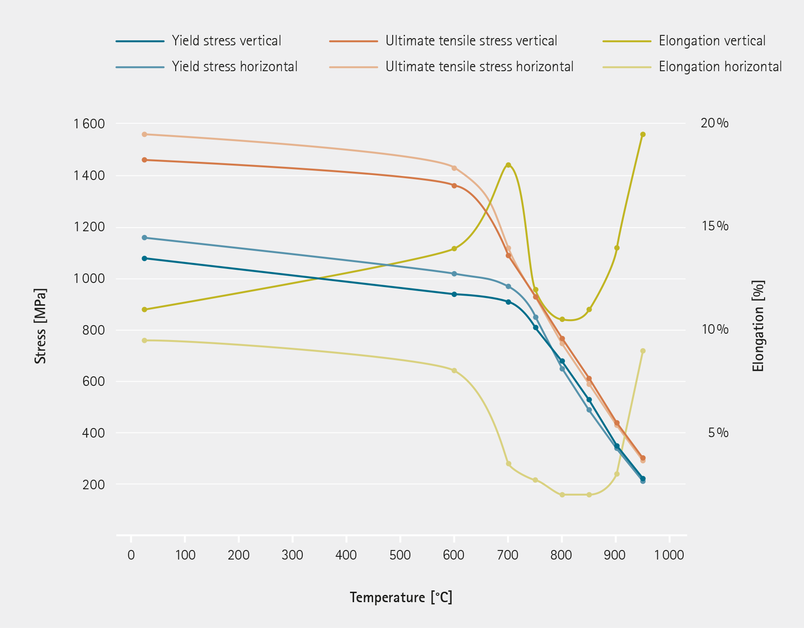

Mechanical Properties Heat Treated

| EN ISO 6892-1 Room Temperature | Yield Strength [MPa] | Tensile Strength [MPa] | Elongation at Break [%] | Reduction of Area Z [%] | Number of Samples |

|---|---|---|---|---|---|

| Vertical | 1080 | 1460 | 11 | - | - |

| Horizontal | 1160 | 1560 | 9.5 | - | - |

Mechanical Properties As Manufactured

| EN ISO 6892-1 Room Temperature | Yield Strength [MPa] | Tensile Strength [MPa] | Elongation at Break [%] | Reduction of Area Z [%] | Number of Samples |

|---|---|---|---|---|---|

| Vertical | 740 | 1090 | 28 | - | - |

| Horizontal | 880 | 1160 | 24 | - | - |

Mechanical Properties

Impact Toughness

Fatigue

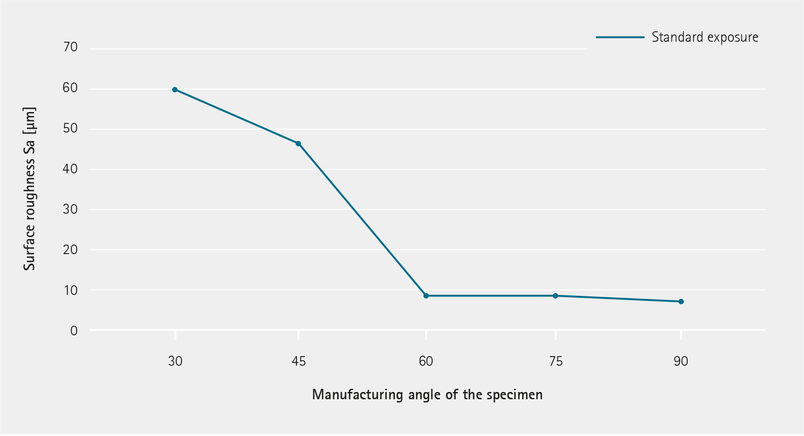

Surface Roughness

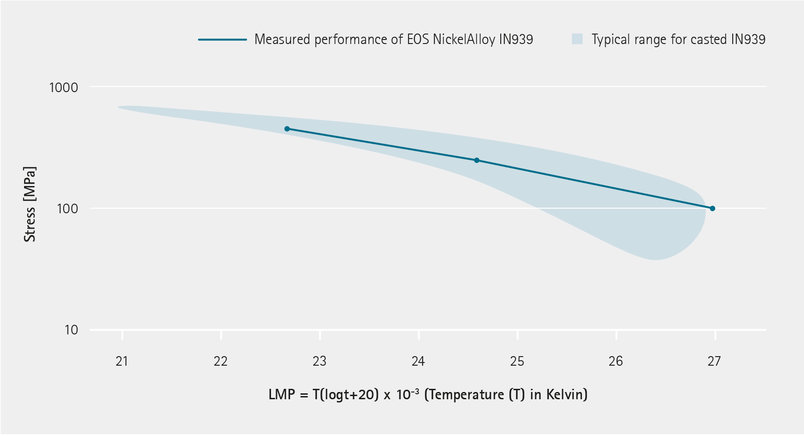

Creep Performance

The stress-rupture performance of EOS NickelAlloy IN939 was tested on vertically oriented samples, in heat-treated condition. No HIP was applied. The data presents the Larson-Miller Parameter values achieved at stress levels of 100 MPa, 250 MPa and 450 MPa. Standard: ASTM E139