EOS NickelAlloy IN939 for EOS M 290 I 40 µm

EOS M 290 - 40 µm - TRL 7

Process Information Metal

This is the process description

| System Setup | EOS M 290 |

|---|---|

| EOS Material set | IN939_040_HiPerM291 |

| Required Software Plan | EOS BUILD |

| Software Requirements |

EOSPRINT 2.6 or newer EOSYSTEM 2.10 or newer |

| Recoater Blade | HSS (High Speed Steel), Ceramic, Carbon Fiber Brush, Nitrile Butadiene Rubber (NBR) |

| Build Platform Temperature | 80 °C |

| Nozzle | EOS Grid Nozzle |

| Inert gas | Argon, Nitrogen |

| Sieve | 63 µm |

| Additional Information | |

|---|---|

| Layer Thickness | 40 µm |

| Volume Rate | 3.6 mm³/s |

| Exposure Strategy | Swimlanes |

| Wall Thickness | Typical 0.3 - 0.4 mm mm |

| Typical Dimensional Change after HT [%] | +0.2% % |

Chemical and Physical Properties of Parts

Chemical composition of built parts is compliant to EOS NickelAlloy IN939 powder chemical composition.

Footnotes Part properties

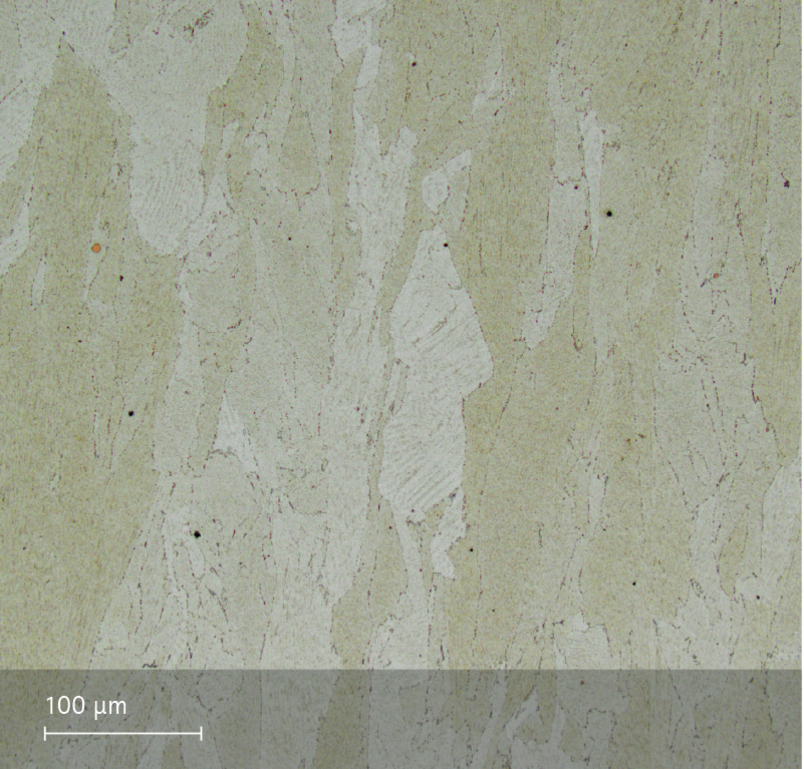

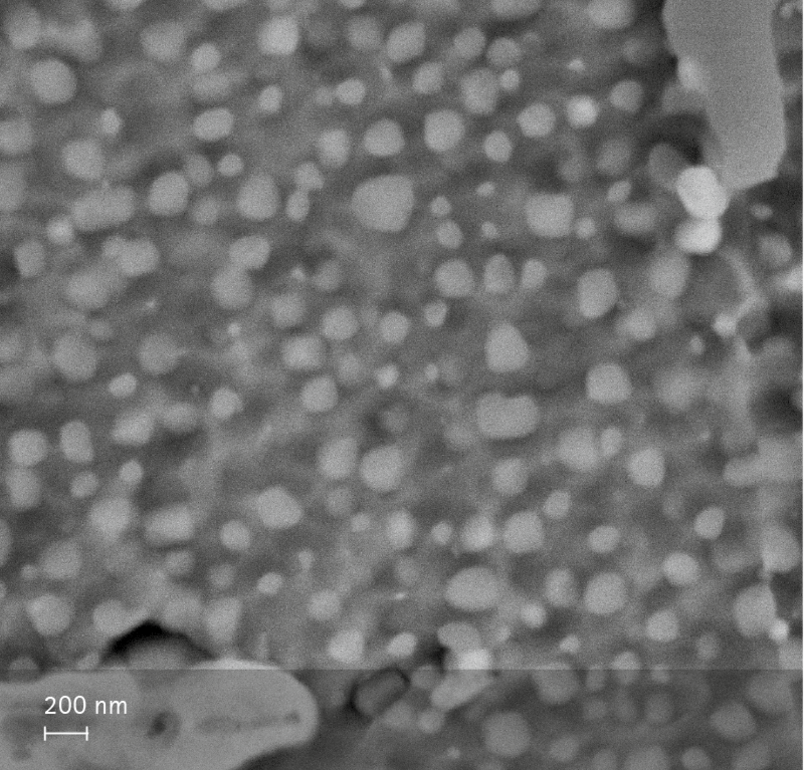

Microstructure of the Produced Parts

| Defects | Thickness | Result | Number of Samples |

|---|---|---|---|

| Average Defect Percentage | - | 0.01 % | 10 |

| Average Defect Percentage | 20 µm | 0.3 % | 10 |

| Density EN ISO 3369 | Thickness | Result | Number of Samples |

|---|---|---|---|

| Average Density | 40 µm | > 8.15 g/cm³ | - |

| Density AMS 2774 | Thickness | Result | Number of Samples |

|---|---|---|---|

| Average Density | 30 µm | 8.10 g/cm³ | 15 |

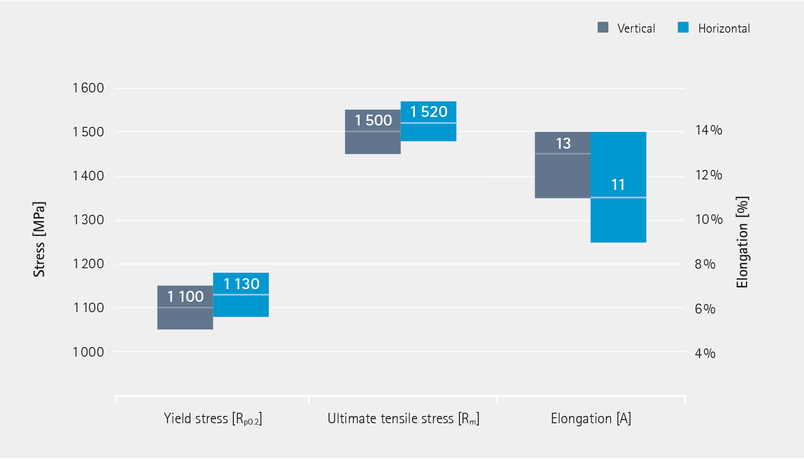

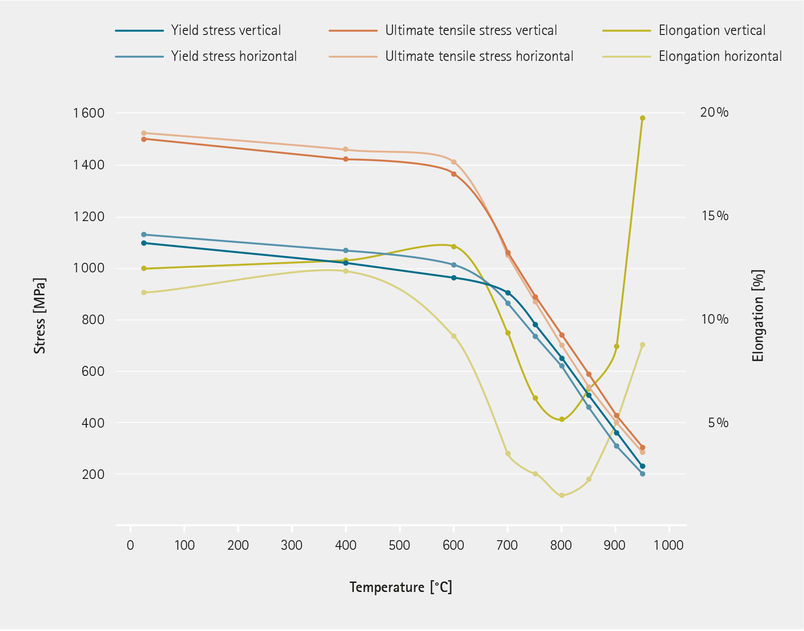

Mechanical Properties Heat Treated

| EN ISO 6892-1 Room Temperature | Yield Strength [MPa] | Tensile Strength [MPa] | Elongation at Break [%] | Reduction of Area Z [%] | Number of Samples |

|---|---|---|---|---|---|

| Vertical | 1100 | 1500 | 13 | - | - |

| Horizontal | 1130 | 1520 | 11 | - | - |

HT description mech properties 1

Footnotes Mech properties

Mechanical Properties As Manufactured

| EN ISO 6892-1 Room Temperature | Yield Strength [MPa] | Tensile Strength [MPa] | Elongation at Break [%] | Reduction of Area Z [%] | Number of Samples |

|---|---|---|---|---|---|

| Vertical | 740 | 1090 | 28 | - | - |

| Horizontal | 880 | 1160 | 24 | - | - |

Hardness

| EN ISO 6508 Heat Treated | |

|---|---|

| Value | 48 |

| Unit | HRC |

| Number of samples | 10 |

| EN ISO 6508 As Manufactured | |

|---|---|

| Value | 10 |

| Unit | HRC |

| Number of samples | 10 |

| EN ISO 6508 As Manufactured | |

|---|---|

| Value | 33 |

| Unit | HRC |

| Number of samples | 10 |

Impact Toughness

| EN ISO 148-1, Charpy-V As Manufactured | |

|---|---|

| Typical Impact Toughness | 110 |

| Layer Thickness | 20 µm |

| Specific Exposure Set | Default |

HT description Impact toughness

Footnotes Impact toughness

| EN ISO 148-1, Charpy-V As Manufactured | |

|---|---|

| Typical Impact Toughness | 120 |

| Layer Thickness | 30 µm |

| Specific Exposure Set | Default |

HT impact toughness 2

Footnotes impact toughness 2

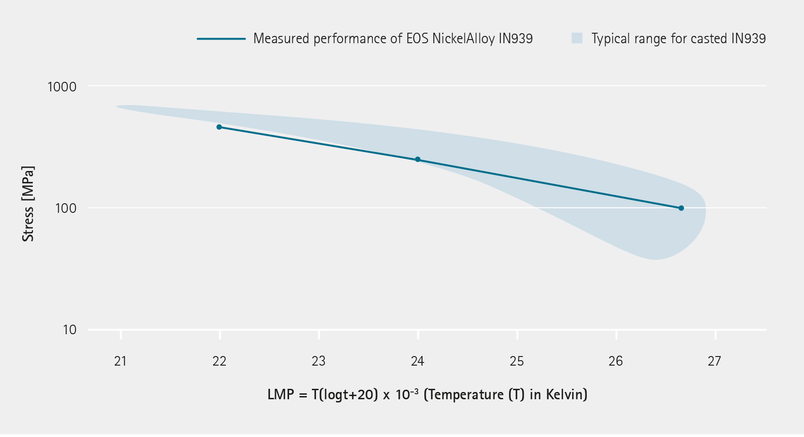

Stress Rupture Performance

| AMS 2774 As Manufactured | Stress [Mpa] | Temperature [°C] | Time to Rupture [hrs] | Elongation [%] | RA [%] |

|---|---|---|---|---|---|

| Vertical | 10 | 25 | 1 | 15 | 16 |

| Horizontal | 11 | 16 | 2 | 18 | 19 |

stress rupture performance description

Fatigue

HT Fatigue - NOT SHOWING UP!!

Low cycle fatigue performance of horizontally and vertically oriented samples at temperatures of 25 °C, 650 °C, 750 °C and 850 °C. The data represents cycles to failure for different strain amplitudes. No HIP was applied. Method, standard, cycles: axial, strain controlled testing according to ASTM E606

Footnotes for Fatigue 1

| As Manufactured | |

|---|---|

| Fatigue Strength [MPa] | 550 |

HT description fatigue 2 - not showing up!

method fatigue 2

Footnotes fatigue 2

Thermal Conductivity

| AMS 2774 | Orientation | [W/m*K] |

|---|---|---|

| As Manufactured | Vertical | 10 |

| As Manufactured | Horizontal | 20 |

HT Description thermal conductivity 1

Footnotes Thermal cond 1

HT thermal conductivity 2

Foot notes thermal conductivity 2

Surface Roughness

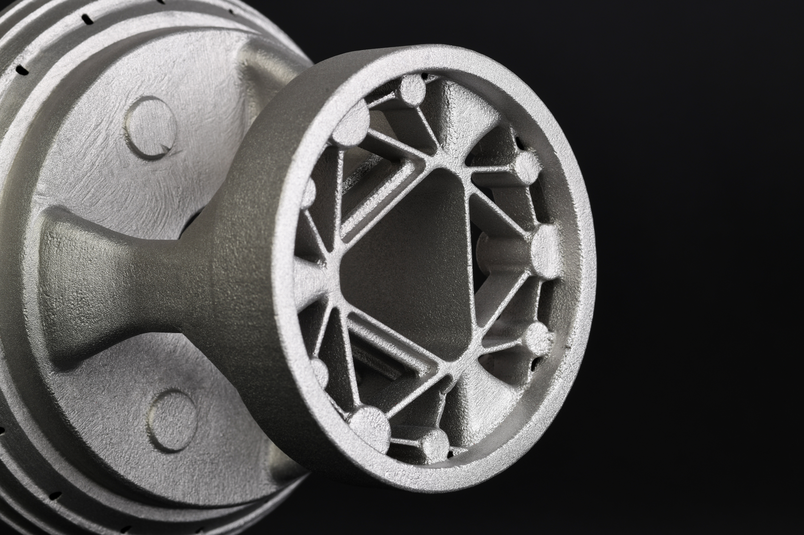

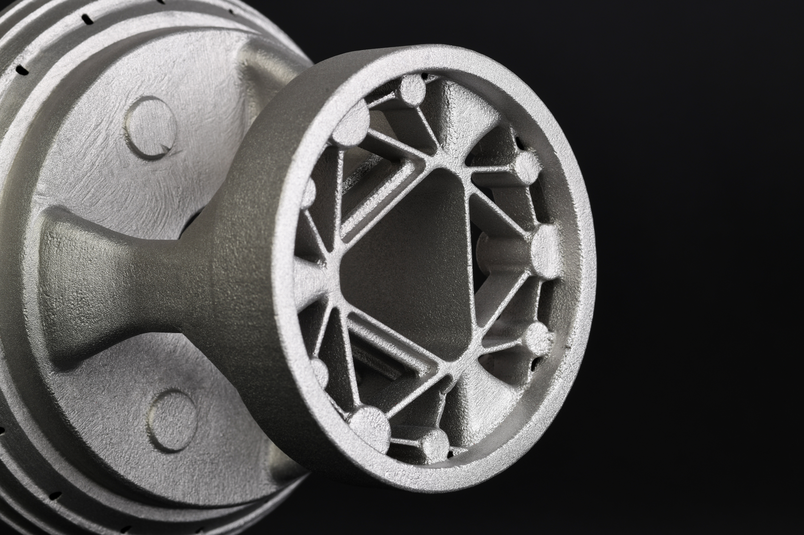

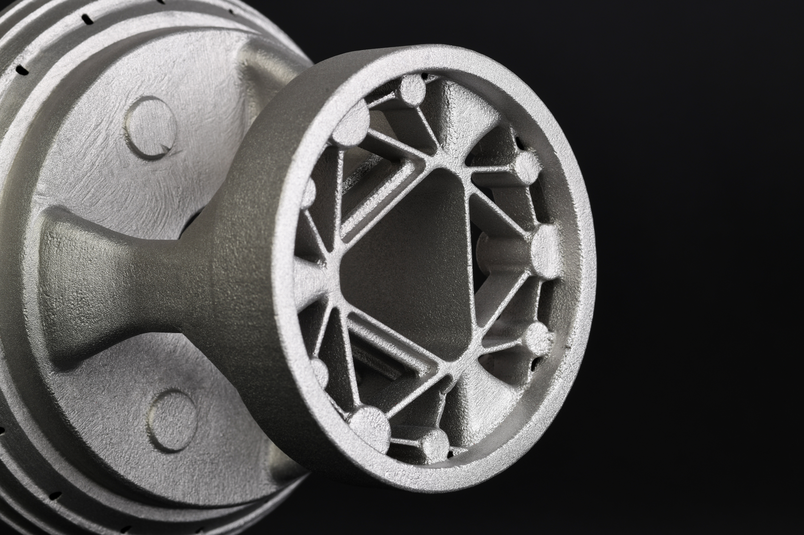

EOS NickelAlloy IN939 parameters were developed for optimized dimensional accuracy of internal cooling features, which are essential to hot gas path components in gas turbines. This comes with a compromise on downskin roughness. Whenever possible, for parts where optimized dimensional accuracy of internal cooling features is not needed, EOS recommends to switch off downskin exposure, to improve downskin roughness and buildability at low angles, and to increase process speed.

Creep performance

| AMS 2774 As Manufactured | |

|---|---|

| Value | 110 |

| Unit | MPa |

Footnotes Misc. add prop. 1 : The stress-rupture performance of EOS NickelAlloy IN939 was tested on vertically oriented samples, in heat-treated condition. No HIP was applied. The data presents the Larson-Miller Parameter values achieved at stress levels of 100 MPa, 250 MPa and 450 MPa. Standard: ASTM E139

add prop 2

| Value | value |

| Unit | unit |

footnotes prop 2

Electrical Conductivity

HT electrical conductivity 1

Footnotes electrical conductivity 1

| AMS 2774 | Orientation | Typical Electrical Conductivity [%IACS] |

|---|---|---|

| HIP / 40 µm / Default | Vertical | 10-15 |

| HIP / 40 µm / Default | Horizontal | 12-18 |

HT elect conductivity 2

footnotes elect conduct 2

| AMS 2774 | Orientation | Typical Electrical Conductivity [%IACS] |

|---|---|---|

| Heat Treated / 50 µm / Application optimised - Inductors | Vertical | > 5 |

| Heat Treated / 50 µm / Application optimised - Inductors | Horizontal | > 6 |

HT elect cond 3

footnotes sample prep 3

Coefficient of Thermal Expansion

| ASTM E228 As Manufactured | Temperature |

|---|---|

| 12.18*10-6/K | 25 – 100 ºC |

| 12.89*10-6/K | 25 – 200 ºC |

| 13.78*10-6/K | 25 – 400 ºC |

| 13.49*10-6/K | 25 – 600 ºC |

| 13.99*10-6/K | 25 – 800 ºC |

| 15.06*10-6/K | 25 – 900 ºC |

Description HT CTE 25-100

Description HT CTE 25-200

Description HT CTE 25-400

Description HT CTE 25-600

Description HT CTE 25-800

Description HT CTE 25-900

Footnotes CTE 25-100

Footnotes CTE 25-200

Footnotes CTE 25-400

Footnotes CTE 25-600

Footnotes CTE 25-800

Footnotes CTE 25-900

| ASTM E228 Heat Treated | Temperature |

|---|---|

| 11.79*10-6/K | 25 – 100 ºC |

| 12.64*10-6/K | 25 – 200 ºC |

| 13.64*10-6/K | 25 – 400 ºC |

| 14.27*10-6/K | 25 – 600 ºC |

| 15.29*10-6/K | 25 – 800 ºC |

| 16.32*10-6/K | 25 – 900 ºC |

Description 2 HT CTE 25-100

Description 2 HT CTE 25-200

Description 2 HT CTE 25-400

Description 2 HT CTE 25-600

Description 2 HT CTE 25-800

Description 2 HT CTE 25-900

Footnotes 2 CTE 25-100

Footnotes 2 CTE 25-200

Footnotes 2 CTE 25-400

Footnotes 2 CTE 25-600

Footnotes 2 CTE 25-800

Footnotes 2 CTE 25-900